Bio Refinery

The ambition of PectCof is to provide a technological solution for the huge amounts of coffee pulp that are produced worldwide. Therefore we have developed a biorefinery technology that yields a functional food ingredient called Dutch Gum.

The idea behind PectCof is to transform coffee cherries, a side stream of the coffee production chain, into valuable food ingredients. PectCof technology uses a biorefinery concept with green chemistry (no use of solvents) and state of the art biotechnology (like membrane filtration) to do so. PectCof technology unlocks the potential of coffee pulp as a source of multiple food ingredients, at the same time detoxifying the side stream produced by the second most traded commodity in the world. The focus is on Dutch Gum as first market introduction, but side streams from the process include Food Grade water binding fibers, fruit sugars, caffein, antioxidants and the beautiful red color of the coffee cherry.

PectCof technology consists of a biorefinery approach in which we make use of green chemistry (no use of solvents) and state of the art biotechnology (like membrane filtration).

The patented process consists of the collection and preservation of the coffee pulp at the country of production. This process includes stabilization, drying, milling and packaging which can take place on the industrial equipment already present at the wet mills where the cherry is separated into green coffee beans and coffee pulp. In the Netherlands we further process the biomass with the use of our patented production process from biomass to functional food ingredients.

Production of coffee pulp/cascara

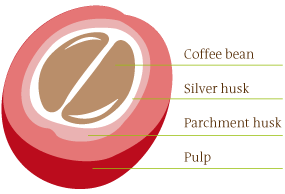

With the production of green coffee beans there is also a side stream of coffee pulp being produced as both are components of the same coffee cherry fruit. Around the world almost 10 million tons of coffee pulp is being produced every year with Brazil, Vietnam and Colombia as the largest producers. This side stream of the coffee production is often being discarded or ends up in a landfill. As most coffee pulp contains water and coffee pulp is landfilled in mass, the leaching out of acidified water can cause acidification of the soil or even worse acidify the water ways.

Coffee is being produced in two different methods, namely the wet and dry method. The wet method uses water to transport the separated green coffee beans and the coffee pulp. With the use of our patented preservation technology this wet coffee pulp can be transformed into stabilized, dried and milled biomass which has value. The dry method uses the sun for drying out the complete cherry after which it is separated into green coffee beans and coffee pulp. As the drying process entails prolonged sun exposure the functional parts within the coffee pulp are broken down by natural processes. This yields a more complex flavor but is less interesting for functional food ingredient producers.